Solving International Automotive Cleaning Challenges

Solving International Automotive Cleaning Challenges

Published

November 18, 2021

For original end manufacturers (OEMS) in the auto industry, preserving the surface of the vehicle and its parts during cleaning is a primary concern. Transporting vehicles from manufacturing plants to dealerships adds an additional layer of complexity—one where nature can take a toll. Additionally, multi-national OEMs must also ensure that manufacturing standards are met as they transport products and processes from one country to another. Some of the certifications that affect the automotive industry are: ISO 9001 Quality Management, ISO 14001 Environmental Management and ISO 45001 Health & Safety. BASF partners with automobile manufacturers to develop performance-tested solutions that meet their unique requirements.

Removing Iron Oxide from Imported Vehicles

Large automobile manufacturers often export and import vehicles via ships where their goods are exposed to the elements, including corrosive salt water. One such OEM approached BASF for a solution for rust removal, specifically found on the lower parts of assembled vehicles that were being shipped overseas.The customer required a final solution that removed the rust yet also protected the vehicles by guaranteeing zero oxidation for six months. In addition, the formula, although developed locally, needed to comply with the manufacturing standards dictated by the manufacturer’s corporate headquarters.The BASF solution for this manufacturer was a formulation combining of Lutropur®, Trilon® M, Lutensol® XP, and Korantin® PP. Some of the most common materials used in the automobile industry are metals like steel, and aluminum, which are subject to corrosion. The salt in sea water acts as a catalyst, accelerating the corrosion chemical reaction process.Just how were these ingredients selected? Lutropur® M is a high purity methanesulfonic acid (MSA). It is a strong and relatively unknown acid that has been available industrially for less than 20 years. Lutropur has unique properties: low corrosivity, high solubility of salts, low toxicity, and it is readily biodegradable. These benefits made made Lutropur the perfect acid for use in the application to break down the salts without corroding the paint and metal of the automobiles.The high-water solubility of Lutropur prevents the precipitation of salts removed from scale.

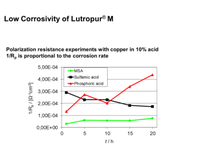

Lutropur M has a low corrosion rate as compared to sulfamic acid and phosphoric acid.

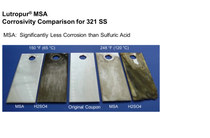

Lutropur® M is also significantly less corrosive than sulfuric acid on stainless steel. Stainless steel comprises 45 to 50 percent of all exhaust systems in the automotive industry.

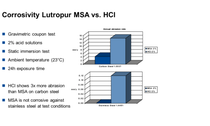

When compared to hydrochloric acid (HCI), Lutropur M shows three times less abrasion on carbon steel. Low-carbon steel is used to make bushing and suspension components as well as clutch housings in automobiles. Low carbon steel is also frequently used in decorative applications such as automotive wheel covers, and in fasteners like nuts, bolts, washers and screws.

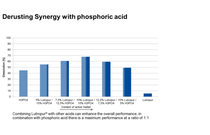

Combining Lutropur with other acids, such as phosphoric acid (H3PO4) can enhance the overall rust dissolution performance.