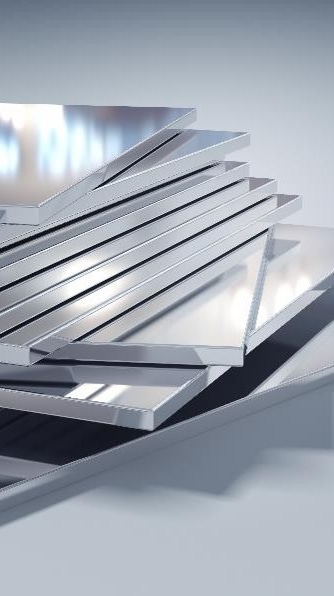

Metal Surface Treatment

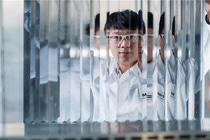

Connected with innovation

We provide customers with the right innovations and competence in metal surfaces treatment to enhance electroplating processes. Our wealth of experience allows us to offer customers a range of electroplating chemicals for different metals and processing steps.

The Metal Surface Treatment industry must meet several technical requirements to improve functionality and service life for example of metal parts in cars, electronic components, screws or tabs. These requirements range from conductivity and solderability to wear and corrosion resistance as well as contact behavior and an even distribution of layers.

Our know-how in the field of specialty chemicals for metal surface treatment and corrosion protection combined with your experience in developing formulations offer the following benefits:

- High-quality decorative effects can be obtained.

- Surfaces of every shape and size can be protected from corrosion and mechanical damage very effectively.

This provides the basis for the long-term success of you and your customers.

.jpg)