Importance of enzymes in medical instrument cleaning

Published: September, 2025

Take a closer look at how enzymes can play a crucial role in enhancing patient outcomes

The Center for Disease Control and Prevention (CDC) estimates surgical site infections (SSIs) represent ~17% of all hospital acquired infections, just behind urinary tract infections1. SSIs are infections that occur at or near a surgical incision within 30 days of a procedure. The CDC estimates that 500,000 cases of SSIs are recorded annually, leading to increased costs and worse patient outcomes across US healthcare. With ballooning costs of healthcare, alongside performance-based reimbursements, preventing these infections has become critical for hospital systems.

$ 3.2

Billion USD

Estimated annual costs

of SSIs in the US2

Inadequate sterilization of medical instruments is a leading cause for SSIs. Hospitals have dedicated surgical technicians who are trained to maintain a sterile environment. However, these surgical technicians rely on cleaning chemistries and processes that ensure that all surgical instruments can be cleaned properly prior to sterilization. Improper cleaning of instruments leads to reprocessing and increased workloads

Types of enzymes used in medical instrument cleaning3

- Proteases: Breaks down proteins such as blood, tissue and mucus. Most essential in medical instrument cleaning

- Amylase: Breaks down carbohydrates present in food or bodily fluids. Applications in post gastrointestinal surgery cleaning

- Lipase: Breaks down fat residues, often from gastrointestinal, endoscopic or orthopedic procedures

- Cellulase: Breaks down cellulose. Applications in post gastrointestinal surgery cleaning

Medical instrument cleaning (MIC) detergents use enzymes, such as protease, lipase, amylase and cellulase, to help break down surgical organic soils. By providing a thorough clean, enzymatic MIC detergents can help reduce reprocessing rates and enhance sterilization outcomes.

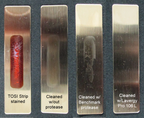

BASF offers a comprehensive portfolio of enzymes that can enable MIC detergent manufacturers to deliver improved cleaning outcomes. For example, BASF’s Lavergy® Pro 106 L outperforms benchmark market proteases in removal of blood soils from TOSI strips within a 15 min soak. With proteinaceous soils being ubiquitous on medical instruments, enhanced protease performance could provide a significant competitive advantage to MIC detergent brands.

Lavergy® Pro 106 L delivers an improved cleaning on proteinaceous soils

So, what are you waiting for? Reach out to your BASF representative and discover the Lavergy® difference.

Related products

Sources

-

U.S. Centers for Disease Control and Prevention - see here

-

Zimlichman E, Henderson D, Tamir O, et al. Health Care–Associated Infections: A Meta-analysis of Costs and Financial Impact on the US Health Care System. JAMA Intern Med. 2013;173(22):2039–2046. doi:10.1001/jamainternmed.2013.9763 - 2

-

Versatility in Every Drop with XEN Enzymatic+ - see here