A New Measure of Manual Dish Performance.

Published

November 18, 2021

In a commercial food environment, the detergent used in manual dishwashing must be safe, efficient, and result in consistently clean dishes. There are several methods that are used to measure the desired performance of a manual dishwashing detergent including the semi-automatic plate wash test, emulsification tests for determining the cleaning performance, foam performance tests, and the epicutaneous patch test for determining the mildness or harshness to skin. There are also opportunities to take additional measurements that may even more closely reflect a product’s ability to perform consistently in the I&I setting.

A Closer Look at APG

When looking for manual dishwashing ingredients that are mild, effective, and eco-friendly, there is no match for alkylpolyglucosides (APG). APGs are a synthetic, non-ionic surfactant made from renewable resources. The hydrophobe in APGs comes from palm kernel and/or coconut oil, and the hydrophile comes from sugar. APGs are eco-friendly, mild, and good emulsifiers. For all these reasons, we looked more closely at the role APGs can play in increasing the optimal performance measures of a manual dishwashing detergent. The APG selected was BASF’s Glucopon® 600 UP because of its longer alkyl chain, which makes it a superior emulsifier.

Exploring the APG-Betaine Synergy

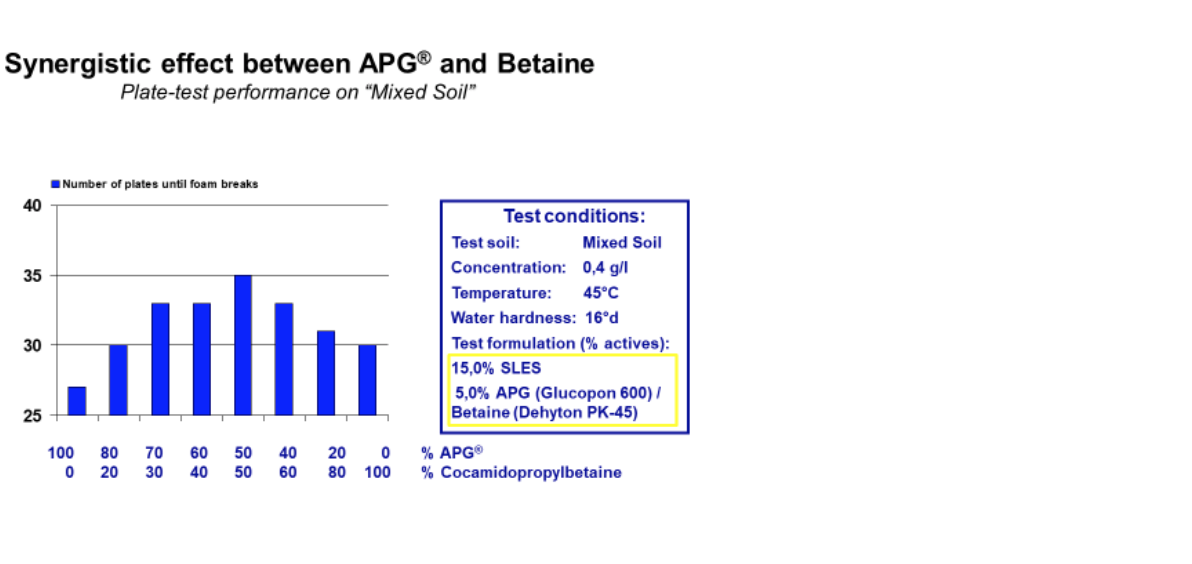

Cocamidopropyl Betaine, or Dehyton® PK-45, is an aqueous surfactant from coconut oil. As a secondary surfactant, it helps to build viscosity, as well as provides good foaming and foam stabilization with excellent wetting properties. Several beneficial synergies are created by combining Cocamidopropyl Betaine and APGs.If we define synergy as when the combination of A and B is greater than either A or B alone, then it is clear in the plate test that measures performance to the foam’s endpoint. In the test system of 15% SLES and 5% APG/Betaine, APGs alone clean about 27 plates, Cocamidopropyl Betaine alone cleans about 30, and a mixture of 50% Cocamidopropyl Betaine and 50% APGs cleans 35 plates.

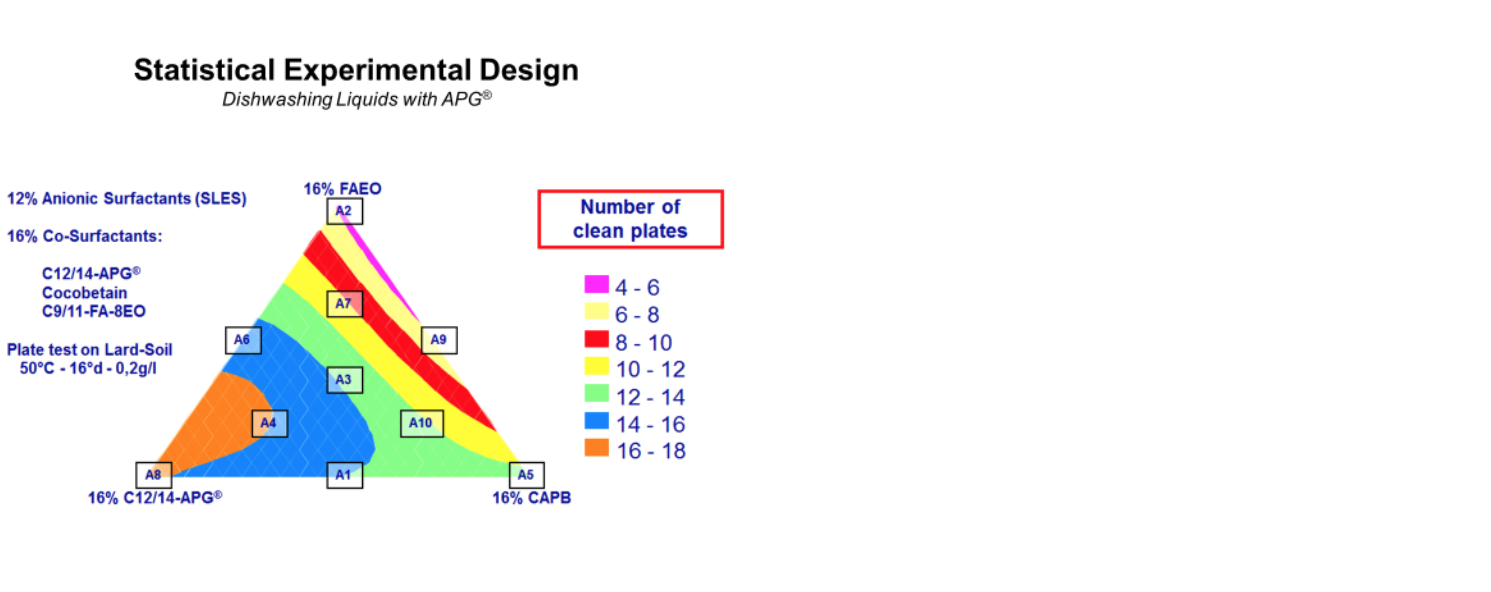

To explore this synergy further, we designed an experiment to look at three varied components. While holding constant a concentration of 12% anionic surfactants, we explored various combinations of FAEO (a linear alcohol ethoxylate), APG (Glucopon® 600) and Cocamidopropyl Betaine (Dehyton® PK-45) to make up the 16% of co-surfactants in the solution. Here again, the optimal combination when measuring to the foam endpoint is the 50/50 combination of APG and Cocamidopropyl Betaine. As soon as the alcohol ethoxylate was added, performance started to diminish.

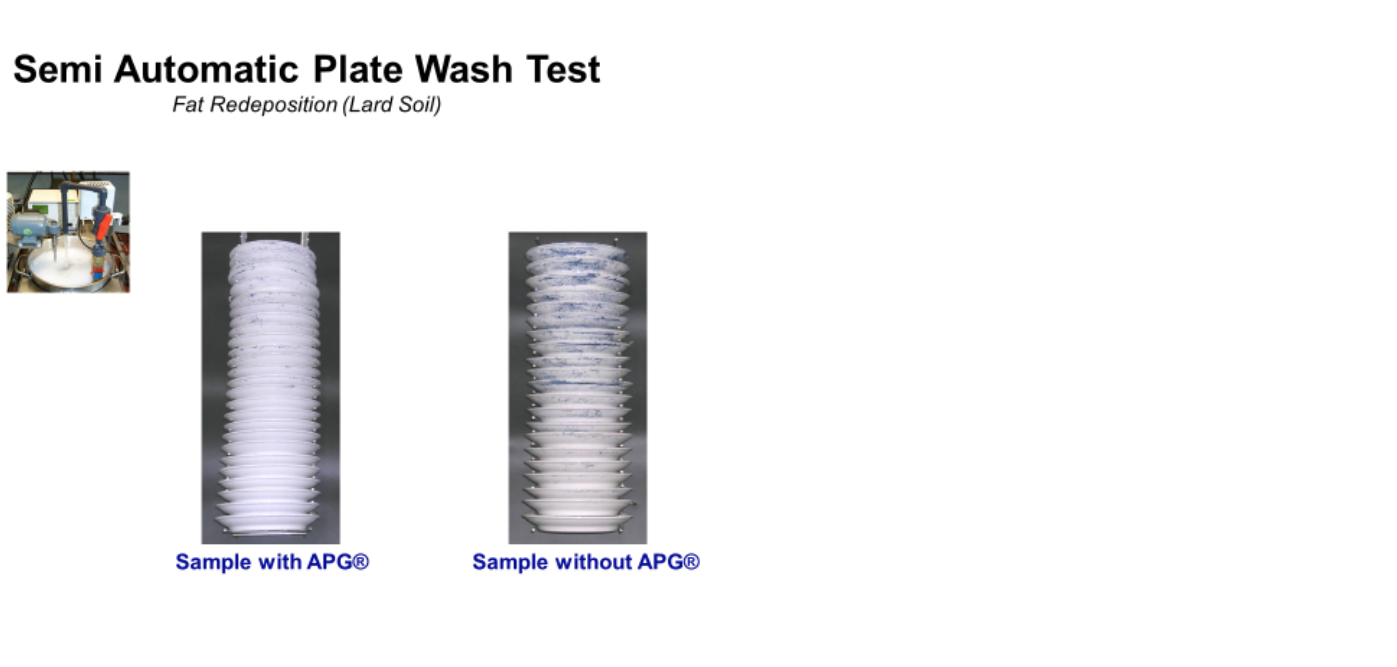

To test this result further, we looked at a new way to measure performance coming out of the plate test. Instead of measuring to the foam endpoint, we counted the number of plates that could be washed before the soil started redepositing on the dish. According to that measurement, the best result was achieved using nearly all APGs where we saw 16-18 clean plates before any redeposition of soil was observed. Without APGs, redeposition occurred after only the third plate was washed.

Optimized Foaming

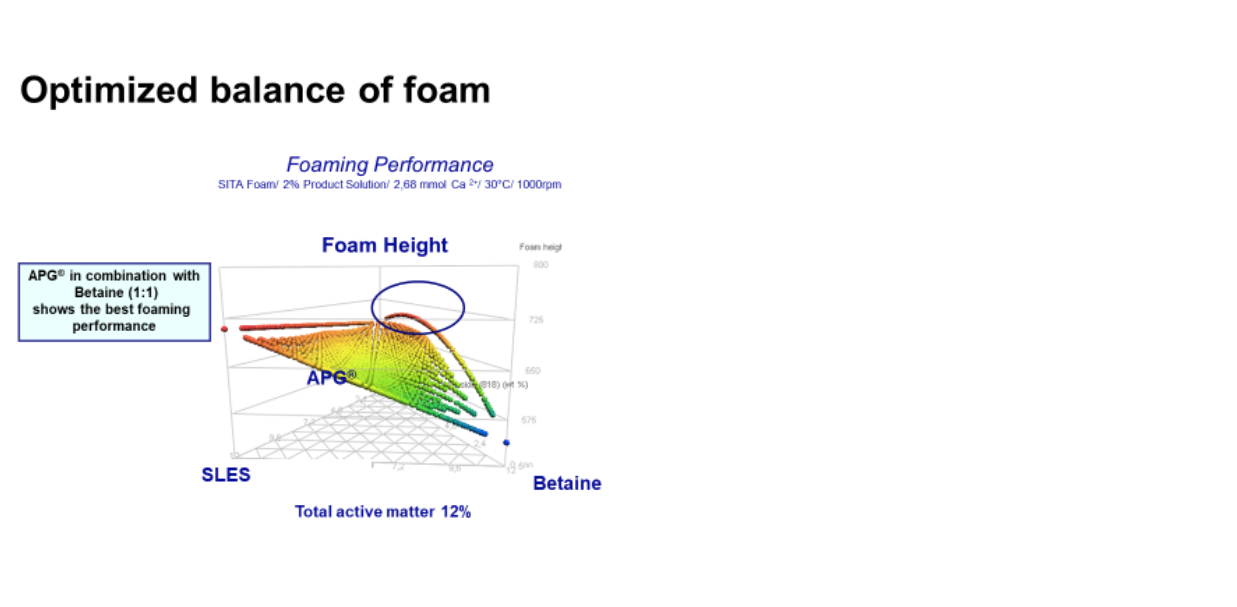

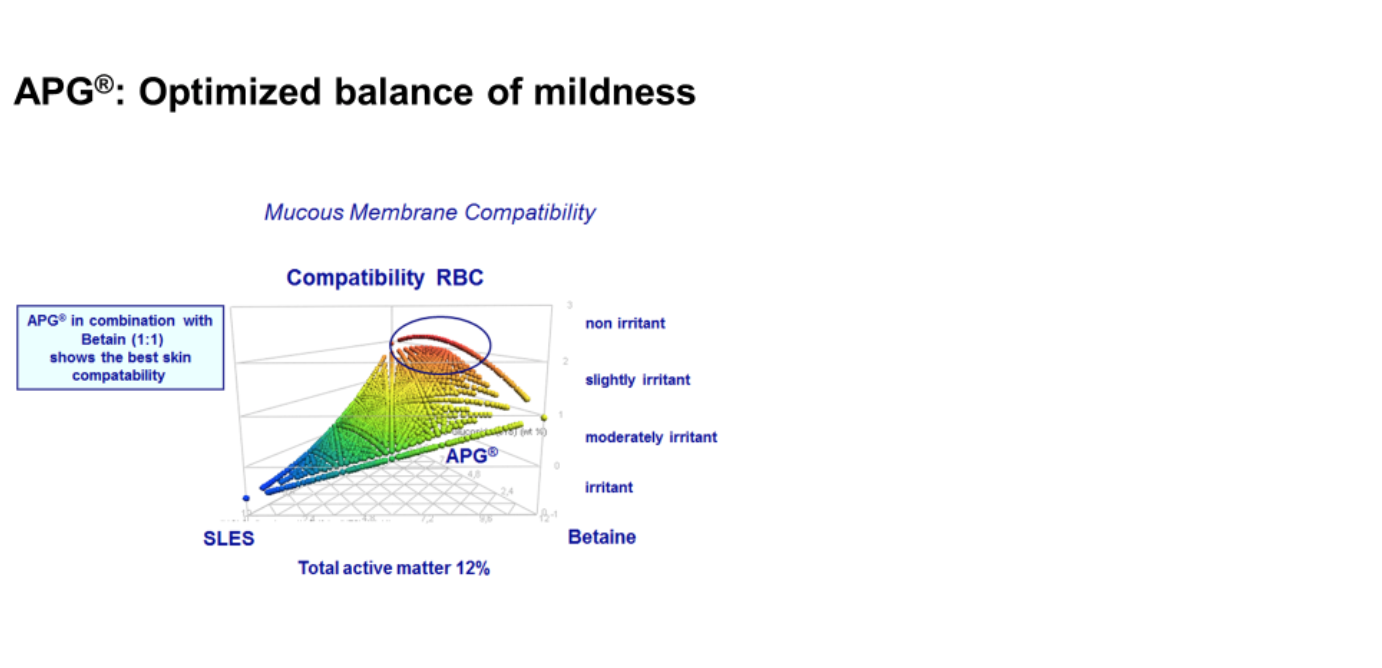

The quality and stability of the foam is an important factor in the perception of a manual dishwashing detergent. The one-to-one combination of APGs and Cocamidopropyl Betaine results in the best foaming performance

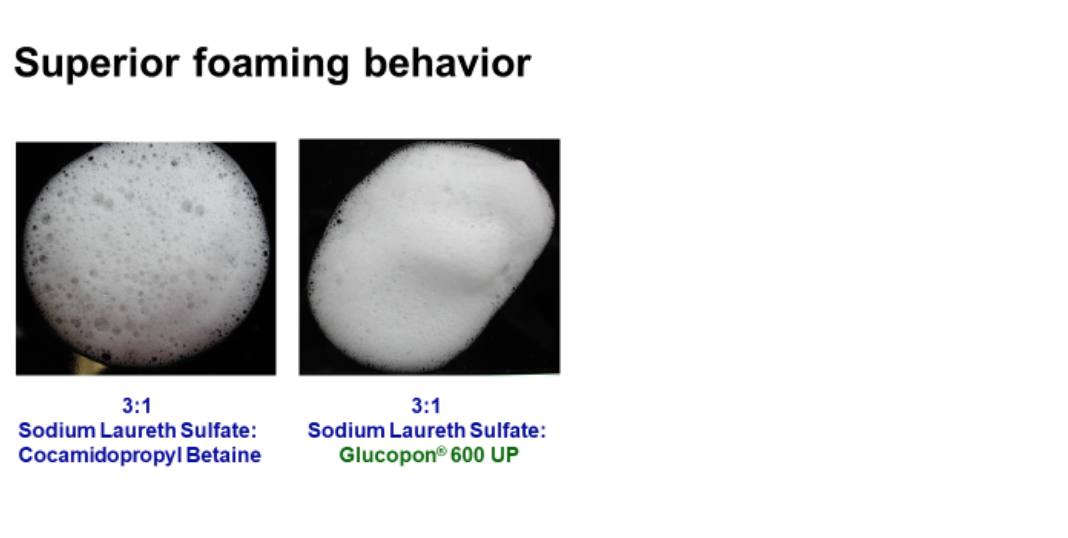

Superior Foam Behavior

When combined with Sodium Laureth Sulfate, Glucopon® 600 UP produces a richer, wetter and more stable foam than the combination of SELS and Cocamidopropyl Betaine.

Excellent Emulsification

An effective manual dishwashing formula will deliver superior emulsification on a variety of oils. In three out of the four soil types tested, Glucopon resulted in the least oil separation, making it the superior emulsifier for that oil type, and hence the surfactant of choice.

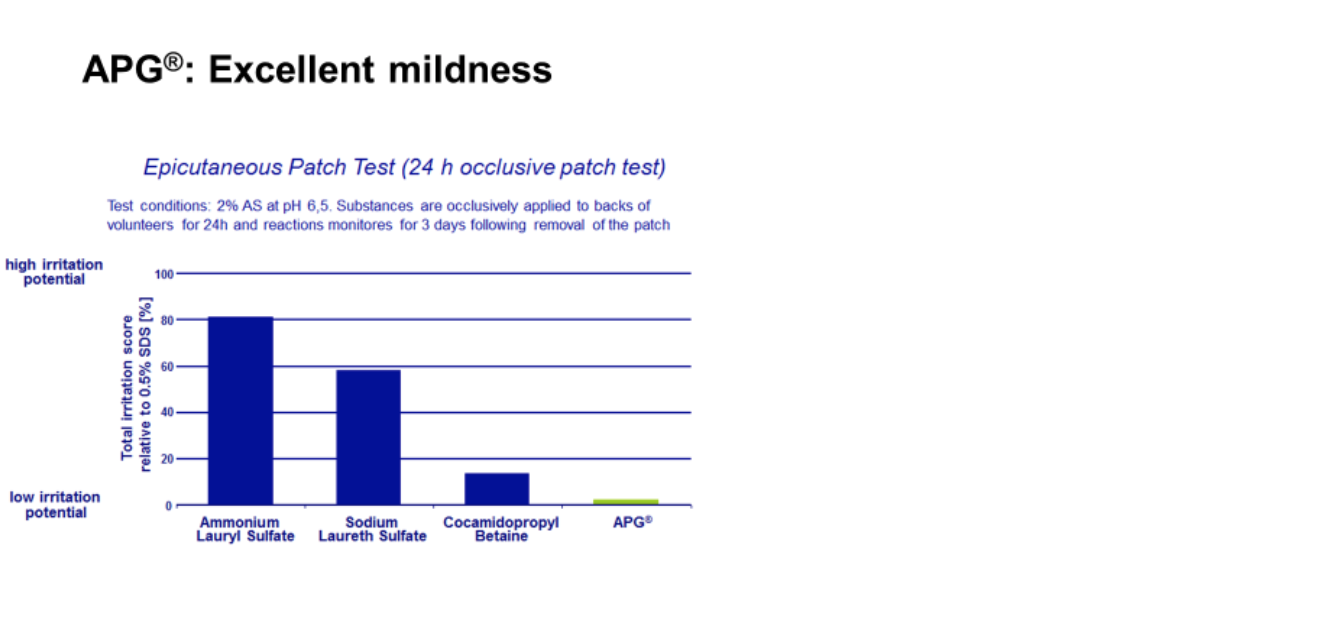

Mild for Skin

In the Epicutaneous Patch Test, APGs demonstrate the lowest irritation potential.

The APGs and Cocamidopropyl Betaine synergy helps mitigate skin irritation even more than APGs alone.

Formulations in Action

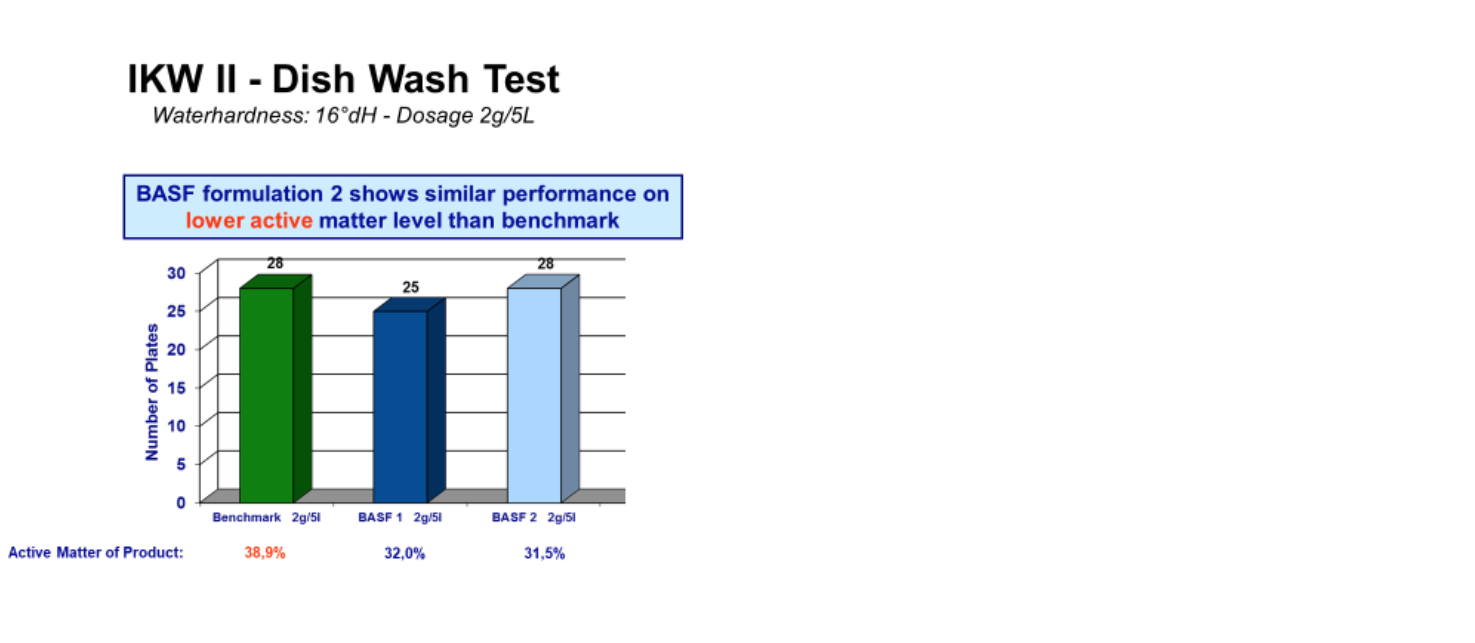

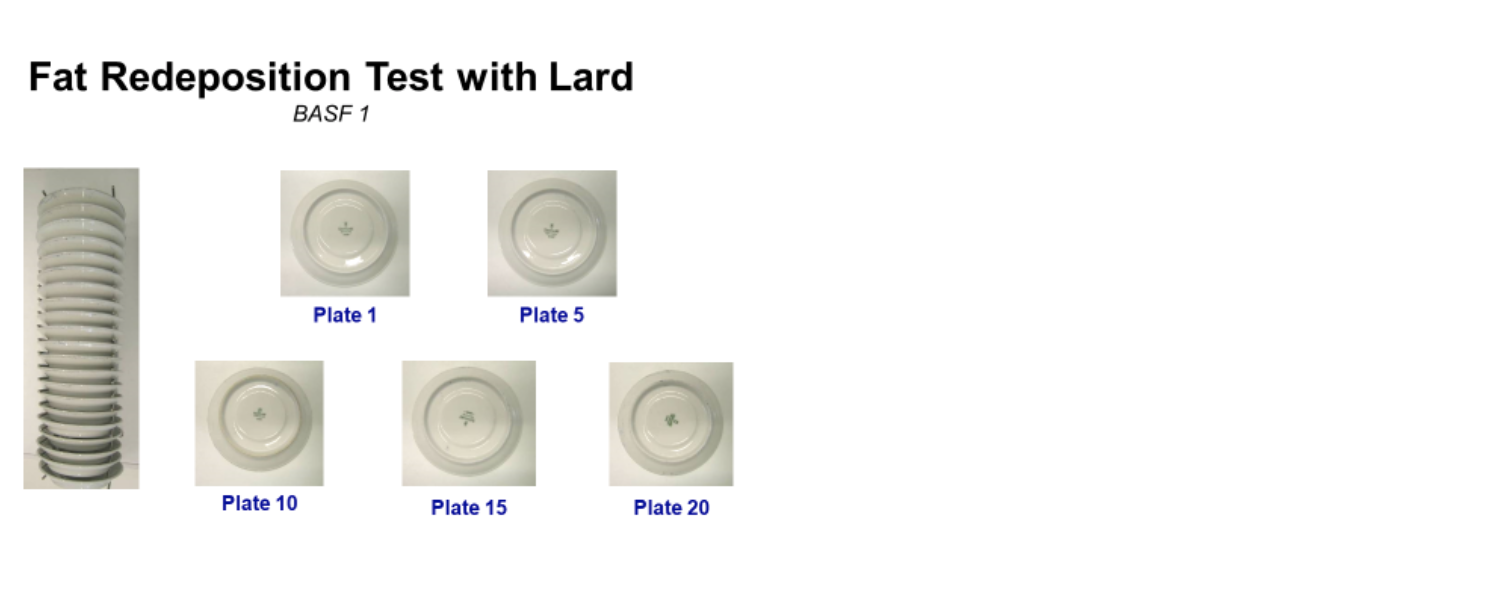

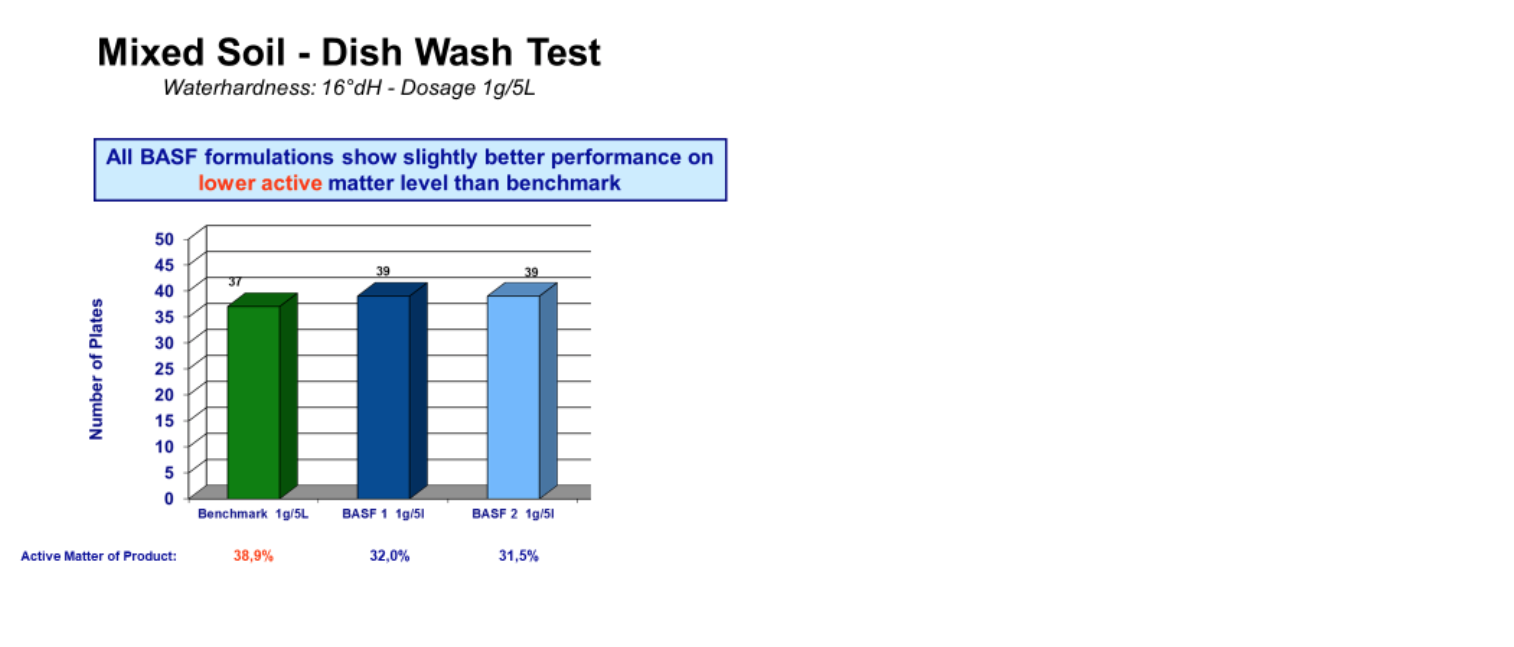

BASF created two formulations to test against the benchmark.

Even with 20% less active surfactant, the two BASF formulations performed as well as the benchmark.

Looking at the redeposition of soil tells an even more powerful story. With the benchmark, soil redeposition started to occur by the fifth plate, and was significant by the twentieth plate. With the BASF formulas, there is very little redeposition, even after plate 20.

The BASF Formulas performed better with mixed soils as well, even with less active surfactant as compared to the benchmark.

Conclusion

The benefits offered by APGs and their synergies present opportunities to improve manual dish detergents for home and I&I customers. From enhancing emulsification to reducing skin irritation and increasing performance, APGs can elevate the potential of manual dishwashing detergents to meet current and future standards of functionality and performance. Creative chemistry with advanced ingredients will help I&I dishwashing detergents meet the advancing cleaning and environmental responsibility requirements of today’s I&I market.