Glucopon® Alkyl Polyglucoside - A Surfactant that Cares

Published

June 25, 2024

When it comes to cleaning products, consumers are looking for more. It has become critical to balance affordability, performance, and sustainable claims.

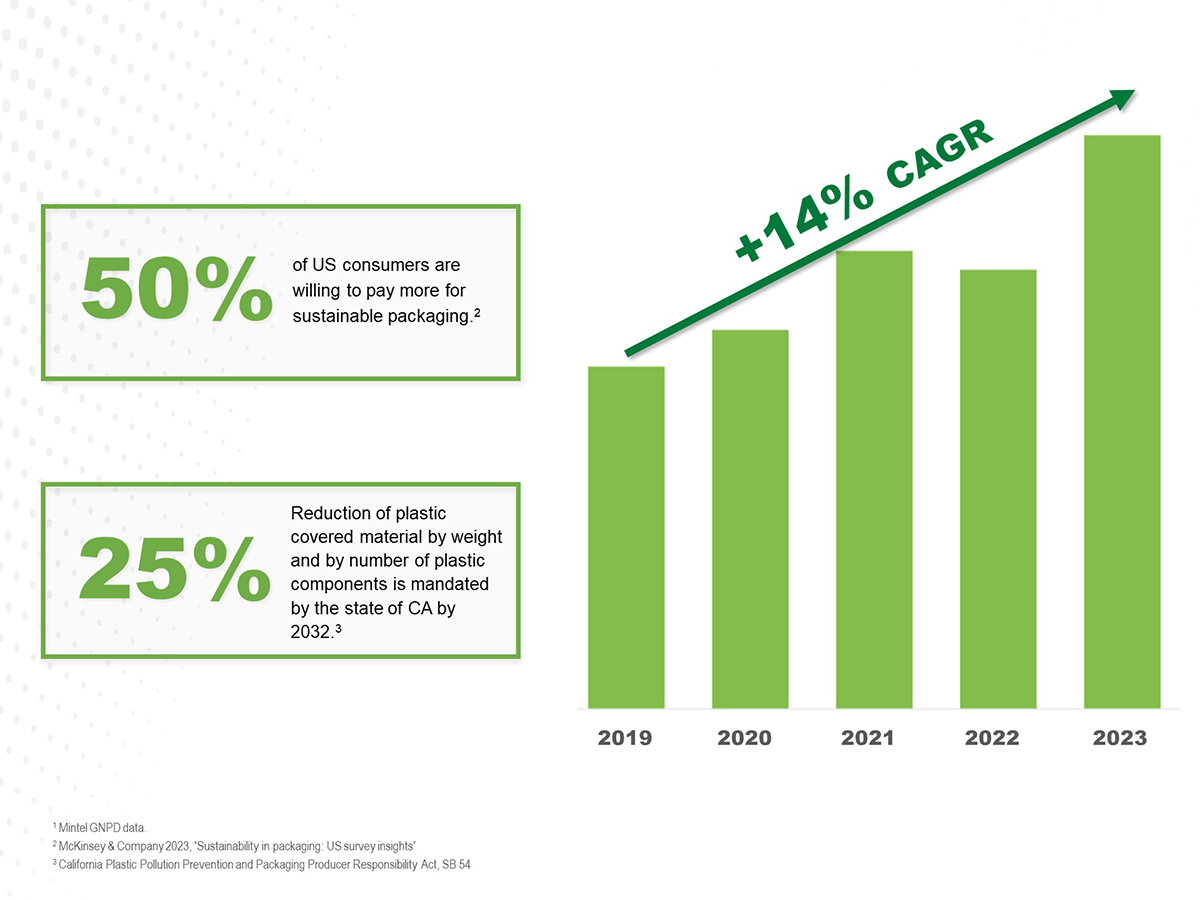

Despite shopping judiciously, consumers have shown a willingness to pay for products with environmentally friendly claims. In fact, US retail sales growth for products with environmental, social and governance (ESG) related claims showed more annual growth from 2018 to 2023, with a CAGR of 6.4% -- compared to the 4.7% of growth products without ESG claims experienced.1

Sustainable packaging has been an area of rapid progress, with consumers increasingly seeing value in more sustainable packaging. In fact, 50% of US consumers are willing to pay more for sustainable packaging.1 The regulatory landscape has also been rapidly evolving, with states like California mandating a 25% reduction of virgin plastic by 2032.2

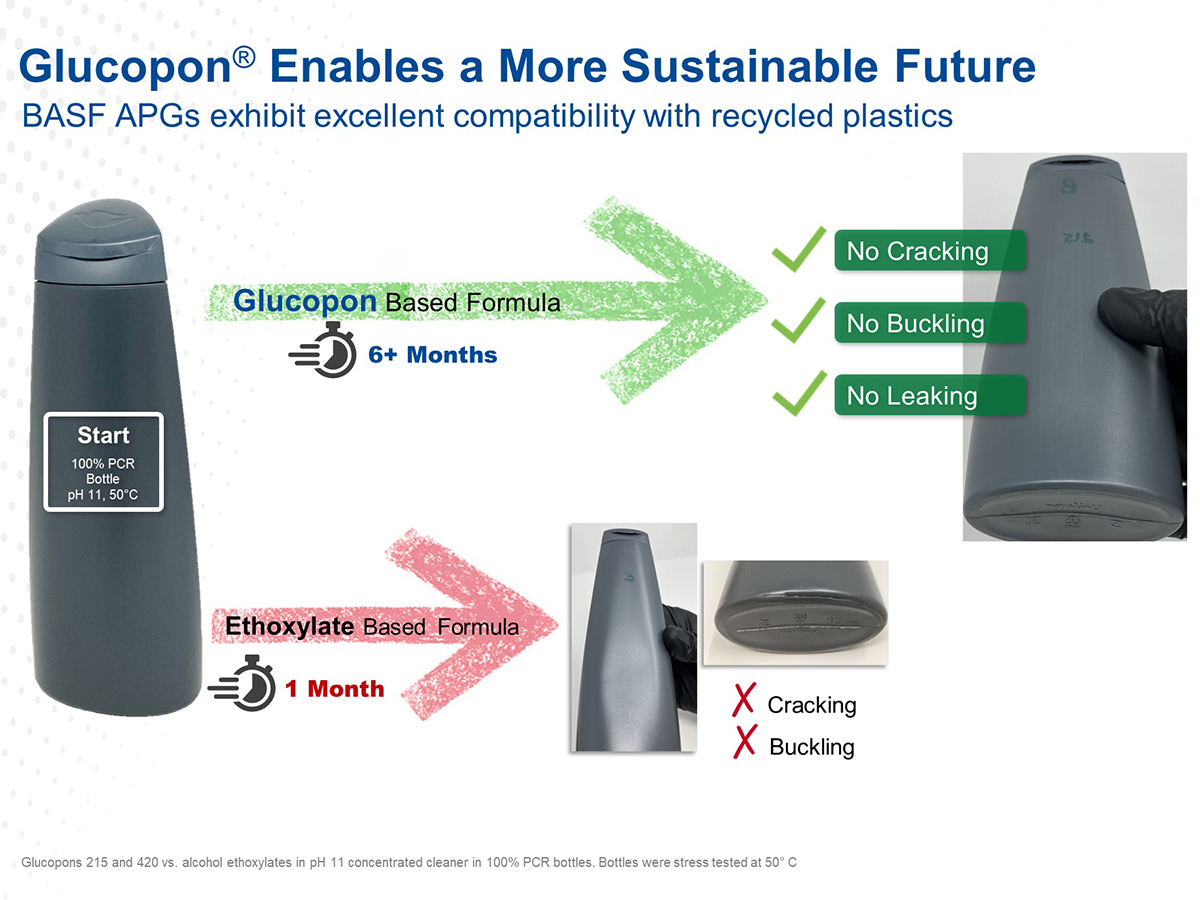

To effectively clean, many ingredients within household cleaners, detergents and dish soap can be harsh on packaging. While their chemical profile makes them powerful against stains and soils, it also means that these ingredients can break down the plastic packaging they are stored in. This incompatibility with packaging is especially prominent when it comes to post-consumer recycled (PCR) plastics. Due to the nature of recycling, PCR plastics contain more residual impurities compared to virgin plastics.3 Therefore, they have a lower degradation temperature and overall more brittle and less robust.4 This means many cleaning products cannot be stored in 100% PCR bottles without causing stress fractures in the packaging.

The question is: how can we develop formulations that can be safely stored in 100% PCR bottles without compromising cleaning efficacy?

The good news is, not all surfactants are equally harsh. And by choosing a surfactant that has better compatibility with PCR plastics, we can preserve performance while enabling increased use of PCR plastic packaging. To put this to the test, we packaged two formulations in 100% PCR bottles and observed the structural integrity of the packaging over at 50 °C over time. One was an alcohol-ethoxylate based formulation, the second was an alkyl polyglucoside-based formulation. We found that the alcohol ethoxylate based household cleaner formulation showed buckling and/or cracking of the 100% PCR bottle after only 1 month – a common issue for this class of surfactants. However, the bottle that held the alkyl polyglucoside-based formulation with BASF’s Glucopon® 600 UP remained intact after 4 months of accelerated testing, with no signs of cracking, buckling, or other symptoms of degradation.

BASF’s portfolio of cleaning ingredients allows formulators to choose from a variety of surfactants, polymers, chelating agents, and more to meet specific desired performance attributes. Our Glucopon APG surfactants are a good choice for those looking to deliver cleaning while increasing the amount of post-consumer recycled plastic in packaging.